/ CNC Repair

RENISHAW BALLBAR TEST

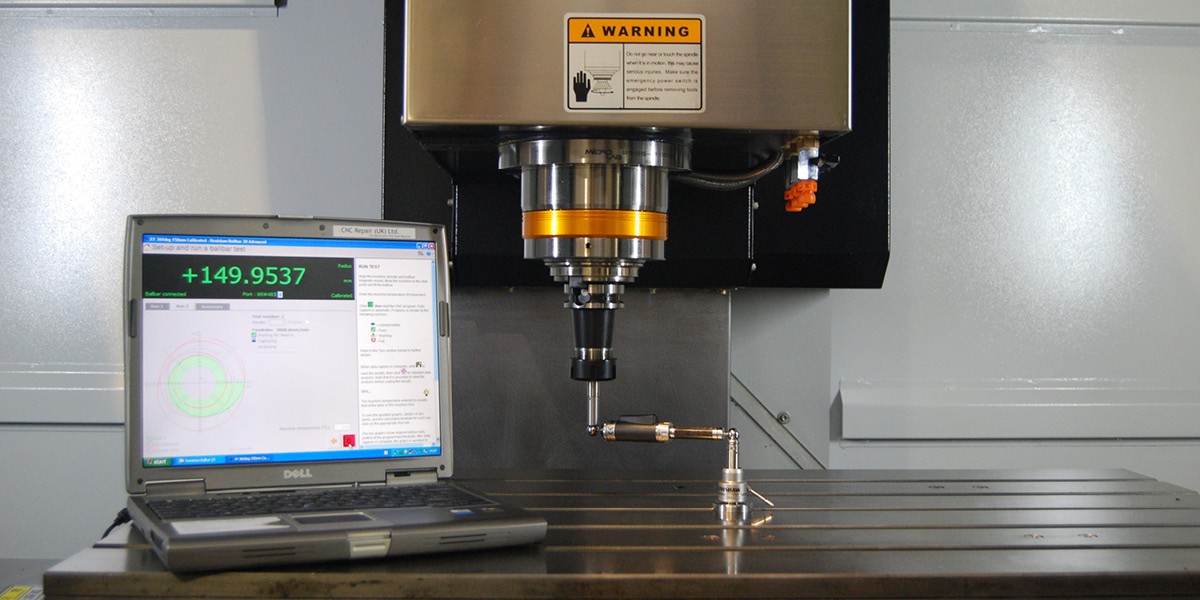

Renishaw Ballbar Test

Ballbar testing provides a simple, rapid check of a CNC machine tool’s positioning performance to recognised international standards (e.g. ISO, ANSI/ASME etc) allowing users to benchmark and track the performance of their machines and to quickly diagnose problems that may require maintenance and the error sources that produce them.

How does ballbar testing work?

The Renishaw QC20-W ballbar is a precision measuring instrument (capable of measuring to + or – 1um of accuracy). It collects data on axis movements when moving in a circular motion. Any deviation from a perfect circle is measured. From the collected data problems with the machine’s geometry such as squareness and straightness can be determined. Also dynamic errors such as ballscrew problems, backlash, reversal spikes, servo mismatch, stick slip can also be determined.

In addition to providing a ballbar testing service and reports to I.S.O standards, (with analysis of results), we also offer a comprehensive corrective action service to bring your machine tool back to the standard you require. This can include ballscrew repair / replacement, slideway repair / regrind & backlash elimination.

Through ballbar testing we can help you:

• Accurately verify a machine’s performance.

• Achieve tight manufacturing tolerances.

• Verify a new machine’s accuracy at commissioning.

• Check machines after a “crash or collision” to ensure machine is able to achieve manufacturing tolerances, or to identify possible causes of machining errors.

Renishaw Ballbar Testing

CALL TODAY FREEPHONE ON 0800 043 1800

We have Engineers based in the Midlands & throughout the UK supporting a wide range of companies. From small machine shops to national & global businesses. Having a track record of 96% of ‘fix on the first day’ makes us the natural choice for breakdown call out.

Our Services

CNC SERVICING

Breakdown Repair

In House Maintenance

Ballbar Testing

Looking For CNC Repair or CNC Machine Tool Services?

CNC Repair (UK) Ltd can provide you with an ‘in house’ CNC maintenance support package manning our customer’s sites on both a long and short time basis.

Contact

Tel:

0800 043 1800

Email:

support@cncrepair.co.uk

CNC Repair (UK) Limited

Unit 4 Spalding Road Business Park,

Bourne,

Lincolnshire PE10 9LF

Navigate

DMG Spindle Repair

When it comes to CNC machines, the spindle is a critical component that plays a vital role in the...

HSD Spindle Repair

When it comes to precision machining and high-speed cutting operations, many manufacturers choose...