HSD Spindle Repair

When it comes to precision machining and high-speed cutting operations, many manufacturers choose Italian spindle builder HSD. HSD electro spindle’s are a crucial component that plays a vital role in ensuring the efficiency and accuracy of your CNC machinery. However, like any mechanical device, electro spindles are subject to wear and tear over time, leading to issues that can impact the performance of your equipment. In such situations, it is essential to address any problems promptly and efficiently through proper repair and maintenance procedures.

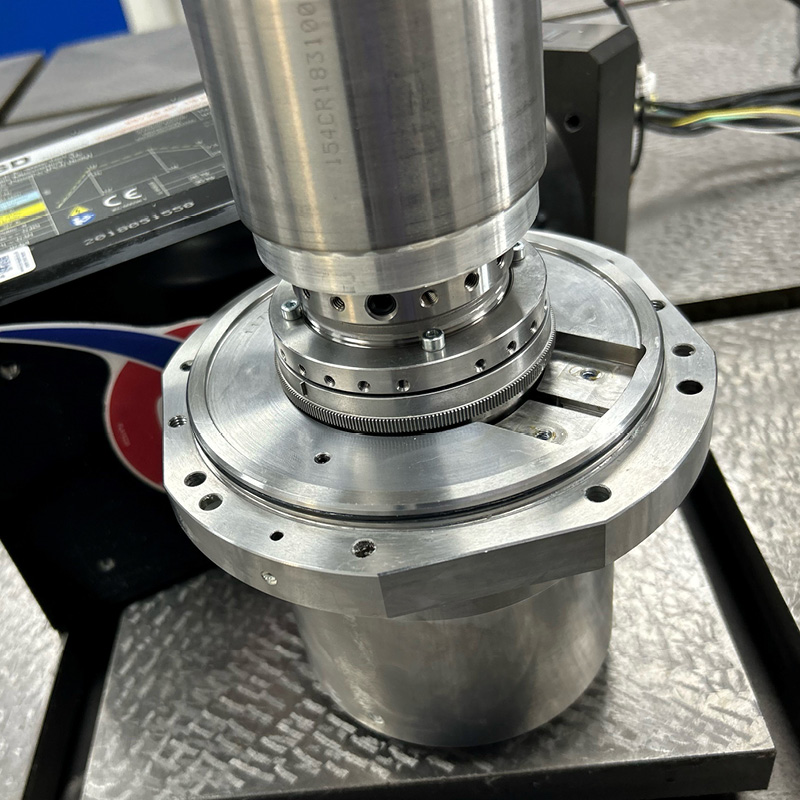

The HSD electro spindle is renowned for its high-speed rotation capabilities and precision engineering, making it a popular choice for industries such as woodworking, aerospace, and automotive manufacturing. This sophisticated piece of equipment consists of intricate components such as bearings, shafts, stators, and rotors and often an encoder, all working together to deliver optimal performance during cutting, milling, and drilling operations.

Common Issues and Symptoms

Over time, a HSD electro spindle may experience issues such as excessive noise, vibration, poor cutting performance, or even complete failure. These problems can arise due to various factors, including lack of lubrication, worn-out bearings, electrical faults, or overheating. It is crucial to identify the root cause of the issue promptly to prevent further damage to the spindle and the associated machinery.

The CNC Repair (UK) Ltd Repair Process

Repairing an HSD electro spindle requires a systematic approach to diagnose, troubleshoot, and address the underlying problem effectively. Our trained technicians with expertise in spindle repair conduct a thorough inspection of the spindle to identify the faulty components and assess the extent of the damage. This may involve disassembling the spindle, inspecting individual parts, and testing for performance to pinpoint the source of the problem accurately.

Once the issue is identified, the repair process may involve tasks such as bearing replacement, shaft alignment, rotor balancing, and electrical troubleshooting. Specialized tools and equipment are often used to ensure the precise reassembly of the spindle and testing of its functionality before reinstallation into the machine.

Importance of Professional Service

Given the complexity and precision of the HSD electro spindle, it is crucial to engage the services of a reputable repair centre like CNC Repair (UK) Ltd that are experienced in handling machine tool spindles. Our professional repair services not only ensure that the spindle is restored to optimal performance but also help prevent future issues and downtime that can impact your production output.

In conclusion, the repair of an HSD electro spindle is a critical process that requires careful attention to detail, technical expertise, and quality service. By following the proper spindle repair procedures and entrusting your spindle to CNC Repair (UK) Ltd, you can prolong the lifespan of your equipment and maintain the efficiency of your machining operations. Remember, a well-maintained electro spindle is key to achieving precision, speed, and reliability in your manufacturing processes.

Contact

Tel:

0800 043 1800

Email:

support@cncrepair.co.uk

CNC Repair (UK) Limited

Unit 4 Spalding Road Business Park,

Bourne,

Lincolnshire PE10 9LF

Navigate

DMG Spindle Repair

When it comes to CNC machines, the spindle is a critical component that plays a vital role in the...

Haas spindle repair and rebuild

American machine tool builder Haas build a wide range of quality machine tools. Due to their...